Country

Australia

Application

Drinking Water

Water source

Bore Water

Filtration solution

Containerised WTP

Background

The existing Water Purification Plant (WPP) was constructed in 1981 and has a design treatment capacity of 1.2 megalitres per day.

Over the decades, the aging infrastructure and outdated treatment processes have led to increased maintenance demands and a high level of operator intervention to sustain functionality.

To ensure a reliable and consistent supply of potable water while reducing operational inefficiencies, the client has initiated a full replacement of the site WPP.

The upgrade project will involve:

• Complete replacement of all treatment process units at the site to ensure efficient raw water purification.

• Modernisation and standardisation of the instrumentation, control, and automation systems, enabling both local and remote monitoring and operation of the facility.

Challenge

The raw water sourced from the bore field locations cannot be classified as potable due to elevated iron, turbidity, and colour levels.

These parameters exceed drinking water standards and pose a significant challenge to effective treatment.

Solution

Amiad designed and supplied a containerised water treatment plant (WTP) with a treatment capacity of 68 m³/hr.

The system is fully integrated and engineered to treat bore water drawn from two 1 megalitre supply water storage tanks. The plant features a multi-barrier approach to ensure removal of contaminants and pathogens, producing water that meets drinking water standards.

Treatment process includes:

• pH correction

• Pre-chlorination

• DMI-65®* media filtration for iron and manganese removal

• UV disinfection for pathogen inactivation

• Post-chlorination for residual protection

About DMI-65® Media

DMI-65® is a catalytic filtration media engineered for efficient removal of dissolved iron and manganese. Its unique micro-porous structure enables:

• Iron removal to below 0.001 ppm

• Manganese removal to below 0.001 ppm

The media acts as an oxidation catalyst, allowing for immediate oxidation and filtration of precipitates without the need for extensive retention time.

*In countries which the trademark is Registered, and TM in countries which it is not formally registered.

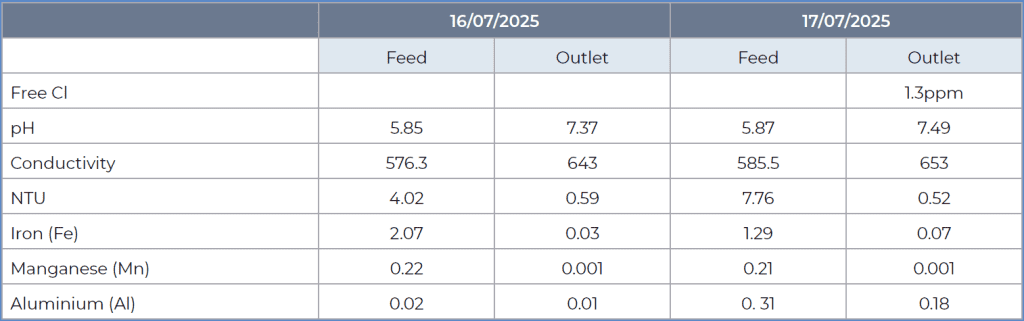

Results

The containerised WTP provided a compact, modular and efficient solution, addressing all key challenges at the site.

The plant now delivers safe, clear, and compliant drinking water, with significantly reduced operational burden and improved automation.